Bangladeshi Manufacture Accept Oem/odm Service Denim Shorts Women Classic Skinny Jeans Pant For Women's From Bangladesh

内部产品

Product Name | Women Denim Jeans |

Fabric Composition | 100% Cotton 99% Cotton 1% Spandex 98% Cotton 2% Spandex |

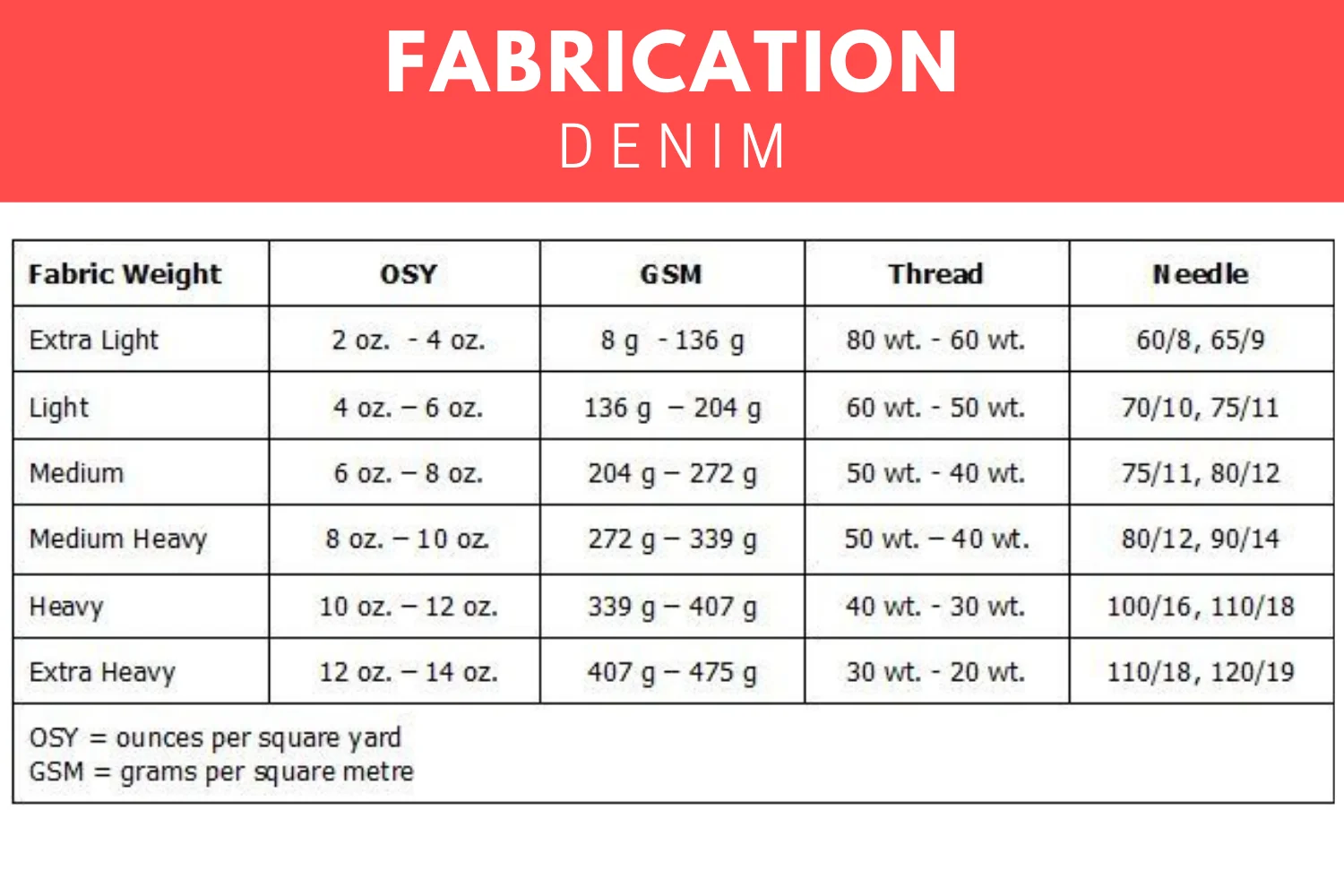

Weight | All available in Ounce |

Color | Customize as per buyer requirements |

Wash/Shade | As per customer requirements |

Measurements | Customize As per buyer requirements |

MOQ | 100pc per shade |

Sample | Development within 7 Days |

Packing & Packing | Standard Export Package |

Place of Origin | Bangladesh |

Brand Name | Custom Brand |

Model Number | Custom Number |

Feature | QUICK DRY, Breathable, Plus Size, Sustainable, Color Fade Proof, Others |

Fabric Weight | Custom |

Supply Type | OEM service |

Material | Spandex / Cotton |

Technics | WASHED |

Fit Type | Regular |

Wash | Medium, colored, Enzyme Wash, SAND WASH, BLEACH WASH, Destroy Wash, Bleach Stone Wash, Chemical Wash |

Closure Type | Zipper Fly |

Waist Type | High |

Jeans Style | Straight |

Style | Casual |

Length | Full Length |

Fabric Type | Softener |

Decoration | None, Button, Lace, Bow, Ripped, Hole, Patchwork, Tassel, WASHED, Pockets, Ruffles, Embroidery, Tie Dye, Lace Up, Painted, Bleached, Side Stripe, Scratched |

7 days sample order lead time | Support |

Pattern Type | Solid |

Product Type | JEANS |

Product name | Women Denim Jeans |

Gender | Female |

Keywords | Hot Women Jeans |

Color | Customized Color |

Size | Customized Size |

Design | Customized Designs |

Season | 4 Seasons |

Type | Causal Wear |

Product Design & Sample Development

We work closely with our clients design team to develop styling in accordance to clients specifications. Then, we analyze your specs & go into sampling.

Samples Approved by Client

Upon sample approval from client, our merchandising team goes to work. Also we will issue a Proforma Invoice against buyers PO's so they can proceed opening the LC.

Prepare Your Order

Before production, we plan & coordinate the entire production process systematically to ensure all orders are delivered on-time, on budget and according to customers' exact specifications.

Proceed Bulk Production

Fabrics Production

Our QA Team closely monitors the entire fabrics making process so the final products is as per buyer's requirement.

Cutting

Fabric cutting is the first stage of the actual manufacturing of the garments. Thus, cutting requires a fair amount of precision.

Printing

Embroidery

If embroidery is applicable, the fabric cut pieces are also sent to our embroidery facilities to be embroidered. The next stage of production is stitching process.

Sewing

Our well equipped factory has more than 500 State-of-the-Art stitching machines of international standards are fully capable to carry out the sewing process with precision.

Ironing

After garments are fully iron/steam pressed, the next step is Quality Control to ensure that goods are as per buyer's instruction.

Quality Control (Q.C.)

After the garments are sewn, Q.C. Team checks measurements, styling, trimming and any rejections before passing to the next stage of production.

Folding & Packing

After garments are fully Q.C. passed, the next step is Ironing & Folding as per buyer's instruction before the finished products goes into cartons.

Shipment

Upon shipping clearance from client, we coordinate & dispatch consignment by trucks & ensure the goods safely reaches at the seaport or airport within due time.

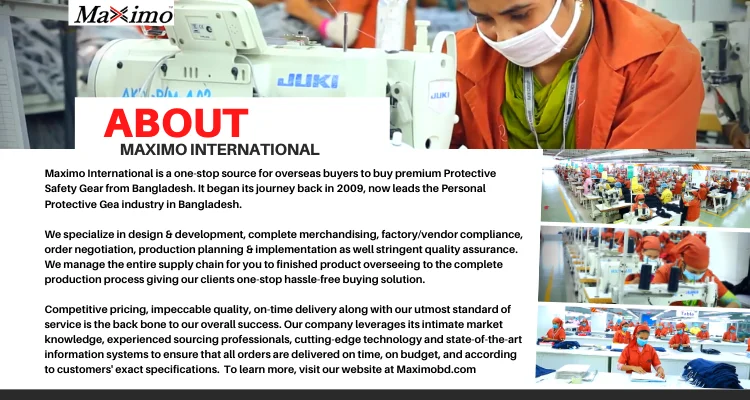

12 Years Experience

We have been manufacturing & exporting Ready-Made Garments since 2009 to Europe & the Americas.

Quality Guarantee

Our entire Quality team takes great pride producing apparels for our valued customers and we firmly stand behind our products until the end-users are fully satisfied!

24-Hour Service

1. What's your main product ? | ||||||

We produce all types of customized knitwear such as promotional tee shirts, polo shirts, shorts, fleece hoodies, sportswear/jackets, sweatshirts, sweaters, jersey, woven dress shirts, sleepwear, lingerie, aprons, cargo pants, terry towels to customers across the globe. | ||||||

2. Why Choose Our Factory ? | ||||||

We have more than 12 years of experience in manufacturing and exporting custom readymade garments worldwide. We safeguard clients interest at all times to ensure all the orders are on track right from the very beginning of the production. We are committed to meeting the needs of our international clientele through competitive pricing, impeccable quality, on-time delivery along with our utmost standard of service. Our company leverages its intimate market knowledge, experienced sourcing professionals, cutting-edge technology and state-of-the-art information systems to ensure that all orders are delivered on time, on budget, and according to customers’ exact specifications. | ||||||

3. What's your factory advantages ? | ||||||

Our factories fully compliant have been audited & certified by WRAP, BSCI, C-TPAT, SEDEX, REACH, ACCORD, OEKO-TEX®, GOTS, SA-8000 as well as ISO 9000. | ||||||

4. What's Your lead time For Bulk production and shipment method ? | ||||||

Our average lead (production) time for bulk is 15-30 days after sample approval. | ||||||

5. Sample Development & Timing | ||||||

Sampling is Free of Charge & normally takes 7-10 business days. However, we request our new buyers take samples at their own courier account. | ||||||

6. Minimum Order Quantity (MOQ) | ||||||

1,200 to 1,500 Pcs Per Color depending on fabrication. | ||||||

7. Payment Method . | ||||||

L/C at Sight (30-60 Days) or Telegraphic Transfer T/T | ||||||